Its single flow induced draft crossflow design offers energy savings in a small footprint installation making it an excellent crossflow cooling tower replacement for.

Marley cooling tower media replacement.

Replacement of heat transfer media or other spot repairs in an older cooling tower will boost cooling capacity in the short term but unless structural integrity also is addressed there will be no improvement in the longevity or structural stability of the cooling tower.

Once the towers are refurbished you can expect another 15 20 years of useful life.

Marley cooling new york 50 south buckhout street suite 204 irvington ny 10533 914 461 0200.

Robert swafford from spx cooling technology demonstrates how to replace the hanging fill in your marley cooling tower.

The factory assembled marley av cooling tower is designed to minimize costs and maximize cooling tower performance through quick easy installation and low maintenance operation.

Marley cooling towers are manufactured in iso certified facilities attesting to our commitment to comprehensive quality processes and systems.

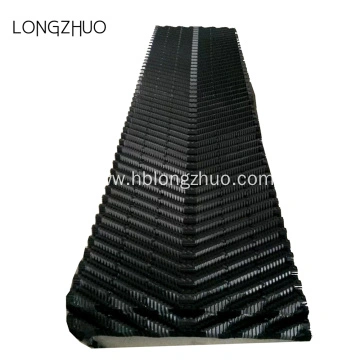

If you are searching for the phrase cooling tower fill material or cooling tower fill media universal tower parts can help when you are ready to purchase cooling tower fill material or cooling tower fill media call universal tower parts today at 602 997 0403 for more information.

Performance for all seasons.

Optimize your cooling process of your towers by increasing the surface area between the water flow.

The marley nc cooling tower is designed to operate year round as specified and will adapt to various energy management approaches.

Marley basingard filter installation and replacement.

Spx cooling technologies embarked on a mission to design and build a cooling tower like no other in the world.

The marley basingard filter saves time and money by simplifying the cleaning of a cooling tower s hot water basin and protecting cooling tower components.